No industry or sector hasn’t been influenced by cutting-edge technology, and the same can be said about the manufacturing sector. However, it is slow to adapt and has yet to fully maximize its operations with the assistant of advance tech solutions available at their disposal.

From AI-supported robots helping in time-consuming, mundane tasks, to modernized technology assisting with virtual assistance and necessary computations – There is much to incorporate. Not to mention with the Internet of Things (IoT) stepping into popularity, its technology is revolutionizing how organizations interact with their assets.

Manufacturing Industry Has Much to Gain from Innovative Tech Solutions

Some technologies are changing the manufacturing industry’s landscape and at a very rapid pace. All it is left is adapting to those solutions and guiding your manufacturing business to success. Since in the era where companies are dependent on technology for growth, advancement, and success- it is imperative to know that those who rely on traditional ways will most definitely be left behind with little revenue to rely on.

Here are 4 technologies that are pushing the manufacturing dynamics to a whole new level.

1. Augmented Reality – Real-Time Assistance

Over time, Information technology and the countless engineers have consistently pushed the boundaries to perfect the emerging technologies – such as AR (Augmented Reality).

Over time, Information technology and the countless engineers have consistently pushed the boundaries to perfect the emerging technologies – such as AR (Augmented Reality).

Its applications are vast that many software development companies are producing, and the manufacturing industry wasn’t neglected either. Manufacturers can now tap into real-time information and guidance and have the necessary instructions and information displayed onto their goggles – increasing productivity and efficiency of the employees.

Not only real-time information, but these AR goggles can help measure and do the menial technical task on the spot through those smart lenses. Also, the goggles can be programmed to warn them of any on-site or technical errors and risks that might arise – keeping the operations running smoothly with little to zero setbacks.

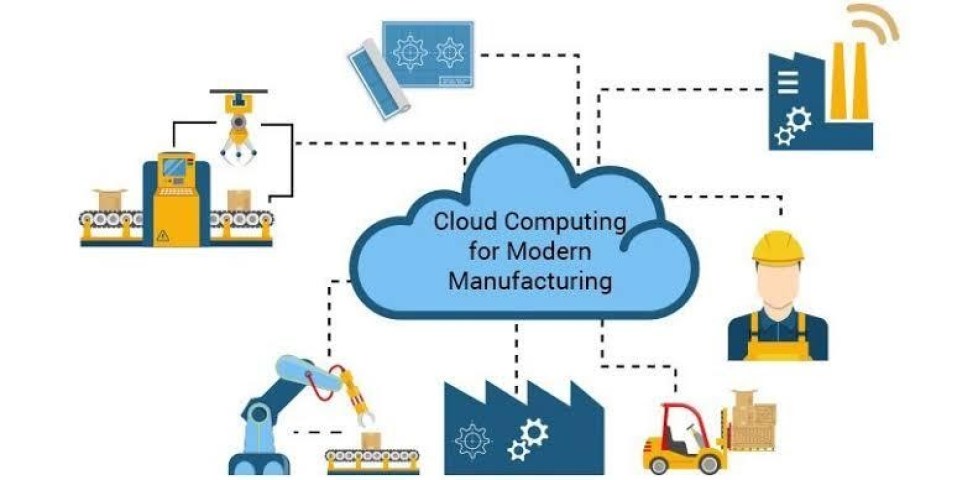

2. Cloud Computing – Safe and Secure Data

Not necessarily the first thing that comes to mind when speaking about technology in manufacturing, but it is the most crucial of them all. How? Since this digital world speaks in data – so does the manufacturing industry that has much to store in their computers. However, these computers can crash or become a victim of a cyberattack, which could cost a huge loss. To curb this, cloud storage is a safe backup storing your entire information on a cloud that can be accessed at any time and from anywhere.

Not necessarily the first thing that comes to mind when speaking about technology in manufacturing, but it is the most crucial of them all. How? Since this digital world speaks in data – so does the manufacturing industry that has much to store in their computers. However, these computers can crash or become a victim of a cyberattack, which could cost a huge loss. To curb this, cloud storage is a safe backup storing your entire information on a cloud that can be accessed at any time and from anywhere.

Cloud computing is a constant technology overall industries – keeping their entire data safe and secure, with the option of easy access from anywhere and at any time.

3. Mobile Technology – Wireless Is the Future

Wearable devices are becoming go-to devices for workers to manage the quick transfer of information or retrieval of it – an inexpensive working experience within the factories. All in all, wireless data sharing has become a necessity for all manufacturing industries as it optimizes the productivity and releases workers of many dependencies. Hence, factory production units are plugged into various devices, such as RFID, Sensors, Bluetooth, Beacons, and many more of such communication technologies.

Wearable devices are becoming go-to devices for workers to manage the quick transfer of information or retrieval of it – an inexpensive working experience within the factories. All in all, wireless data sharing has become a necessity for all manufacturing industries as it optimizes the productivity and releases workers of many dependencies. Hence, factory production units are plugged into various devices, such as RFID, Sensors, Bluetooth, Beacons, and many more of such communication technologies.

These wireless technologies and mobile ERP allow workers to efficiently complete their tasks which results in a high production rate, ultimately increasing revenue.

4. 3D Printing – Faster and Cheaper Production

3D printing technology has evolved from printing minute objects in 3D to now printing fully concrete houses and machinery parts –if we speak only what may concern the manufacturing industry. However, with current 3D printing technology, the entire structure of manufacturing unites has been revamped.

3D printing technology has evolved from printing minute objects in 3D to now printing fully concrete houses and machinery parts –if we speak only what may concern the manufacturing industry. However, with current 3D printing technology, the entire structure of manufacturing unites has been revamped.

Now with so many applications of 3D printing, it has become possible to develop parts and components with extreme precision, which has led to an increase in production size and influx of orders as now with the help of printing units, much complex, and customized units can be printed in lesser time.

These 3D printing machines are affordable with applications that can prove to be profitable for manufacturing companies.

5. Big Data – Increased Visibility and Learned Decisions

Internet of Things, combined with cloud computing, has provided manufacturers with the ability to analyze real-time data produced and gain an in-depth understanding of their business through big-data analysis. This, in turn, allows the leaders to take their business forward in the right direction by improving production, optimizing operations, and addressing issues before they arise.

Internet of Things, combined with cloud computing, has provided manufacturers with the ability to analyze real-time data produced and gain an in-depth understanding of their business through big-data analysis. This, in turn, allows the leaders to take their business forward in the right direction by improving production, optimizing operations, and addressing issues before they arise.

Impressive indeed. The power of IoT coupled with a secure network can give the insight any industry leader would need regarding every operation that is being carried out and efficiently identify points of improvement.

6. Tech Savvy Employees – Growing Necessity

Of course, with reliance on technology and that too in the manufacturing realm is a challenge- not only to find employees that are master of their craft but are also tech-savvy at that. This has led to many open positions that remain unfulfilled for a long time. However, this isn’t a drawback of technology-infused in the manufacturing industry. This challenge can be tackled with effect measures – two of them are as follows:

Of course, with reliance on technology and that too in the manufacturing realm is a challenge- not only to find employees that are master of their craft but are also tech-savvy at that. This has led to many open positions that remain unfulfilled for a long time. However, this isn’t a drawback of technology-infused in the manufacturing industry. This challenge can be tackled with effect measures – two of them are as follows:

- Give adequate training to the existing workforce with the necessary tech skills they require.

- To attract IT professionals into the manufacturing sector, attract them by making your business appealing in terms of career growth, perks, and benefits.

7. B2B2C – Shifting to More Lucrative Avenues

Traditionally manufacturers cater to other companies. Now, they are shifting to a B2B2C model due to the benefits and profits it holds for an industry that was otherwise limited to one pathway. These businesses now have access to a consumer base where they fulfill orders at a retail price rather than a lower wholesale prices for their products. Moreover, you can collect adequate data from your customers and utilize that knowledge to not only cultivate better relationships but also make the necessary improvements within your product.

Traditionally manufacturers cater to other companies. Now, they are shifting to a B2B2C model due to the benefits and profits it holds for an industry that was otherwise limited to one pathway. These businesses now have access to a consumer base where they fulfill orders at a retail price rather than a lower wholesale prices for their products. Moreover, you can collect adequate data from your customers and utilize that knowledge to not only cultivate better relationships but also make the necessary improvements within your product.

Conclusion

These seven tech trends in the marketing industry are shaping its entire infrastructure to one that can be integrated with the modern-day digital world – enabling businesses to identify crucial business needs, investing in required technology, adapting optimized processes ultimately leading to better production, increased revenue, reduced time, and cost optimization.

Author Bio: Zubair is a digital enthusiast who loves to write on various trends, including Tech, Software Development, AI, and Personal Development. He is a passionate blogger and loves to read and write. He currently works at professional Mobile application Development companies that offers top-notch Mobile app development services to clients across the globe.